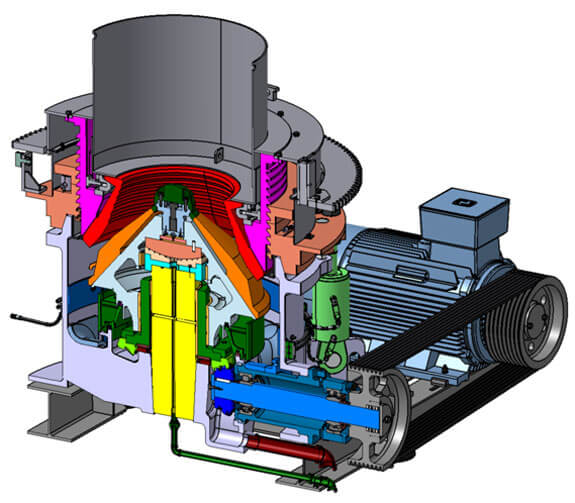

THE NEW UNITEC-FIC15/18 Hydraulic cone crushers are developed to produce sand and fine aggregate with the highest crushing ratio and the least liner wearing. Its powerful driving and new concept crushing mechanism make it possible to get maximum 80% of sand (below 6mm) with the feeding of 6-40mm quarry aggregate.

Furthermore, the liner change cycles are 3-4 months as normal cone crusher liner replacement. Simply by replacing liners, various on-spec products from coarse to fine aggregate can be achieved.

The unique crushing chamber and high speed leads the inter-particle crushing and the high quality cubical shape products. NEW UNITEC-FIC15/18 CONES are greatly easy operation and maintenance with automatic systems such as Automatic sensors for over-loading, Automatic tramp release system, Automatic setting system and Automatic assembling & disassembling system for liner change etc..

Special features & benefits are the below

- Powerful driving and new concept crushing mechanism

- High quality cubical products with inter-particle crushing

- Easy operation and least installation space

- Automatic sensor for over-loading

- Automatic tramp release system

- Automatic setting system

- Automatic assembling & disassembling system for liner change.

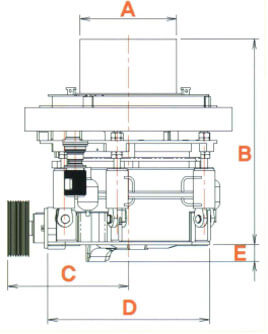

UNITEC-FIC15/18 Cone DIMENSIONS

Notes: The above table is nominal dimensions.

| MODEL | A | B | C | D | E |

| UNITEC-FIC15 | 1100 | 2330 | 1400 | 2060 | 210 |

| UNITEC-FIC18 | 1600 | 2555 | 1885 | 2770 | 80 |

Machine Type & Capacity

Specification

| CRUSHING CAPACITY(TON/HRS) | PULLEY (RPM) |

MOTOR (KW) |

TYPE | FEED OPENING | WEIGH (TON) |

|||||||||

| MODEL | 6 | 10 | 13 | 16 | 19 | 25 | 32 | 38 | CLOSED (MM) |

OPEN (MM) |

||||

| UNITEC FIC15 |

90-110 | 115-140 | 150-185 | 180-220 | 200-240 | 230-280 | 250-320 | 750-1050 | 190-220 | ST | 195 | 235 | 18 | |

| SH | 70 | 115 | ||||||||||||

| UNITEC FIC18 |

175-220 | 230-290 | 280-350 | 320-400 | 365-455 | 405-535 | 445-605 | 700-900 | 300-375 | ST | 140 | 180 | 37 | |

| SH | 260 | 300 | ||||||||||||

Disclaimer

Crusher performance and suggested settings are based on clean, dry, free flowing material with a bulk density of 1.6t/m³ and an average crushing work index and UCS.

The settings shown in the crusher performance chart are indicative only and are based on the crusher receiving an even and homogenous distribution of clean, free flowing and evenly graded feed material.

Feed presentation is crucial in achieving optimum crusher performance. It is strongly recommended that the feed be presented to the crusher in an even and well distributed manner, preferably via a vibrating feeder or belt feeder.

In situations where it is important to maximize the production of fine material from the crusher, it will be necessary for operators to adjust the crusher setting (CSS) to achieve maximum reduction without exceeding available power and crushing force. Operation of the crusher at too fine a setting will result in “ring bounce” or tramping which will lead to major damage if allowed to continue.

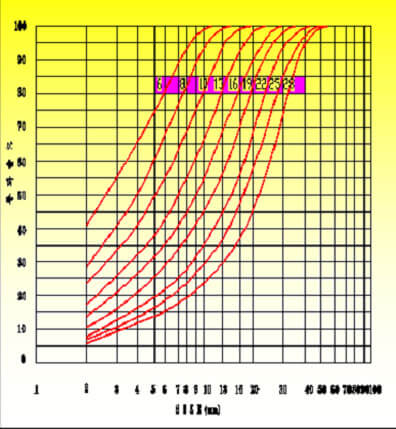

GRADATION CURVES

- % passing through a square mesh depending on the given setting.

- The gradation and capacities shown are depended on the feed gradation, the crushing chamber, the material density, the material cleanliness, its moisture and its crushability.