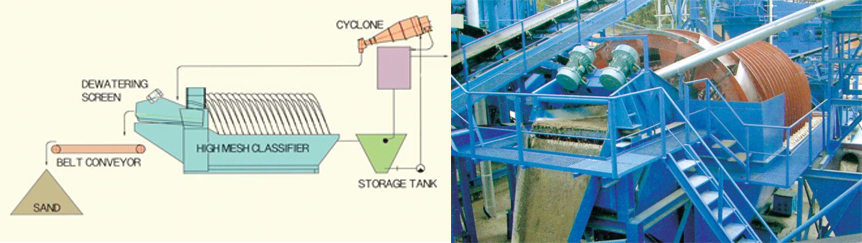

1. SAND CLASSIFIER AND CYCLONE

Washing, high mesh classification,and dewatering are done all at once!!

- This equipment processes simultaneously for sand washing, sludge high mesh classification and dewatering.

- The dewatering screen of the high mesh classifier and the cyclone are organized in one unit.

- Two-stage sludge high mesh classification (stage 1 for H.M classifier and stage 2 cyclone high mesh classification) for 200mesh or below is to remove the sludge alone to produce the complete quality of sand

The definitely effectiveness up to 200mesh!!

- High degree of sand distribution and withdrawal of small grain sand for high intensity.

- The adjustment of Mesh size is available up to #100~ #200

High Mesh Classifier & Cyclone Specification

| Model No. | Capacity (t/h) | Water Q’ty(m3/h) Cut Point | Dimension | Motor (kw) |

R.P.M | Dewatering Screen |

Cyclone | ||||

| Spiral Dia.(m) |

Bucket Dia.(m) |

Tank Length(m) |

|||||||||

| 200mesh | 150mesh | 100mesh | |||||||||

| SYC-3650 | 120 ~ 140 | 190 | 250 | 400 | 3.0 | 3.6 | 5.0 | 7.5 × 1/289 |

1~2 | DS-1024 | Φ650 |

| SYC-3660 | 230 | 320 | 500 | 6.0 | |||||||

| SYC-3670 | 280 | 370 | 600 | 7.0 | |||||||

| SYC-4260 | 180 ~ 210 | 260 | 360 | 570 | 3.5 | 4.2 | 6.0 | 11 × 1/289 |

1~2 | DS-1530 | Φ950 |

| SYC-4270 | 320 | 430 | 700 | 7.0 | |||||||

| SYC-4280 | 370 | 500 | 800 | 8.0 | |||||||

| SYC-4860 | 210 ~ 300 | 290 | 400 | 630 | 4.1 | 4.8 | 6.0 | 15 × 1/289 |

1~2 | DS-1833 | Φ1100 |

| SYC-4870 | 350 | 470 | 770 | 7.0 | |||||||

| SYC-4880 | 410 | 550 | 800 | 8.0 | |||||||

| SYC-5470 | 320 ~ 420 | 530 | 720 | 1150 | 4.7 | 5.4 | 7.0 | 19 × 1/289 |

1~2 | DS-2145 | Φ1100 |

2. SANDUNIT

- High efficiency of classification

- Convenience of installment at the small space

- High efficiency of dewatering

| Sand Unit | Sand Pump | Cyclone | Dewatering Screen | Dimensions | Weight | ||||||||

| Size | kw | Type | Type | Area | kw | A | B | C | D | E | H | ton | |

| 300 × 100 | 6″ | 30 | 650 | 10 × 24 | 2.5 | 2.2 × 2 | 4000 | 2100 | 6200 | 3500 | 2000 | 4400 | 4.3 |

| 400 × 100 | 8″ | 37 | 900 | 10 × 24 | 2.5 | 2.2 × 2 | 4000 | 2400 | 6900 | 3500 | 2100 | 4950 | 5.4 |

| 500 × 100 | 8″ | 45 | 900 | 10 × 24 | 2.5 | 2.2 × 2 | 5200 | 2400 | 7450 | 3800 | 2100 | 5000 | 5.9 |

| 500 × 160 | 8″ | 45 | 900 | 15 × 30 | 4.5 | 4 × 2 | 5200 | 2400 | 7450 | 3800 | 2100 | 5000 | 7.9 |

| 600 × 100 | 10″ | 45 | 1100 | 10 × 24 | 2.5 | 2.2 × 2 | 4100 | 2400 | 8000 | 3950 | 2300 | 5000 | 6.2 |

| 600 × 160 | 10″ | 45 | 2 × 650 | 15 × 30 | 4.5 | 4 × 2 | 4100 | 2400 | 8000 | 4150 | 2300 | 5000 | 7.9 |

| 600 × 200 | 10″ | 55 | 2 × 650 | 18 × 33 | 6 | 4 × 2 | 4100 | 2800 | 8400 | 4200 | 2300 | 5000 | 8.5 |

| 800 × 160 | 10″ | 75 | 2 × 900 | 18 × 33 | 6 | 4 × 2 | 4530 | 2800 | 8400 | 4200 | 2300 | 5000 | 9.2 |

| 800 × 200 | 10″ | 90 | 2 × 900 | 18 × 33 | 6 | 4 × 2 | 4530 | 2800 | 8400 | 4200 | 2300 | 5000 | 9.8 |

| 800 × 300 | 12″ | 90 | 1100 | 21 × 42 | 7.5 | 22 | 4530 | 2800 | 9200 | 4200 | 2300 | 5000 | 11 |

The best dewatering efficiency!!

- Getting the best efficiency to use after production immediately.

- Polyurethane meshes are used and can be available to exchange partly in case of wearing of them

- As an attached of Vibrating Motor, the strong vibration occurs simultaneously available to adjust amplitude of vibration according to physical properties of sand.

| Model No. | Deck | Size(W×L) | Capacity(t/h) | Slope | Motor(kw) |

| SYDS-1024 | 1 | 1000×2400 | 80 ~ 120 | 5˚ | 2.2×2 |

| SYDS-1530 | 1 | 1500×3000 | 140 ~ 170 | 5˚ | 4×2 |

| SYDS-1833 | 1 | 1800×3300 | 170 ~ 220 | 5˚ | 4×2 |

| SYDS-2145 | 1 | 2100×4500 | 220 ~ 300 | 5˚ | 22 |