THE NEW UNITEC-MC Hydraulic cone crushers are developed to produce sand and fine aggregate with the highest crushing ratio and the least liner wearing.

1. Mutual compatible structure of primary cone and secondary cone type

- Replacement of liner aloe enables the conversion of the primary cone type and the secondary cone type.

- Change of use is very easy at the time of plant movement and increase.

2. Concave replacement mechanism

- With the improvement of the liner assembly method, the concave replacement time is shortened.

- Maintenance is possible with the sleeve exchange at the site without welding.

3. Improvement of production volume for 16% or more.

- Compared to same level of model, the production volume is increased for 16% or more.

- The crushing chamber structure is appropriate to optimal crushing mechanism.

4. Hydraulics to open the crushing chamber

- When the crushing chamber is clogged by the mantle in operation, the cleaning time is shortened.

- It improves the operation rate and convenience of facilities.

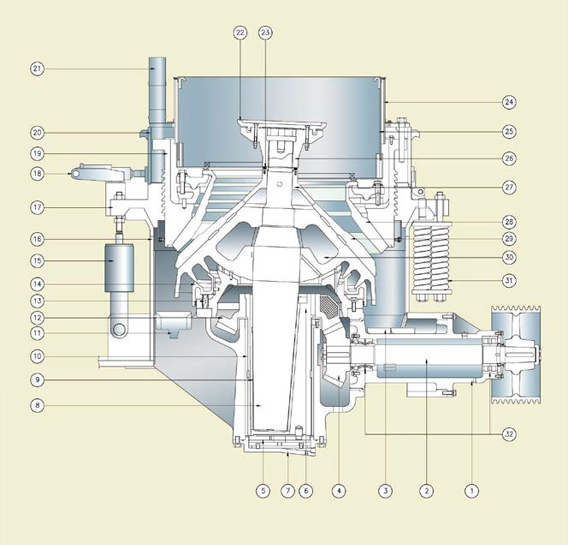

1. Shaft Housing 2. Counter Shaft 3. Housing Liner 4. Bevel Pinion 5. Thrust Plate 6. Eccentric 7. Bottom Cover 8. Main Shaft 9. Eccentric Bush 10.Frame Bush 11.RIB Liner 12.Bevel Gear 13. Spherical Seat 14. Dust Sealing 15. Release Cylinder 16.Main Frame 17. Top Frame 18. Setting Cylinder 19.Top Shell 20. Cap frame 21.Lock Post 22.Distributor 23.Tightener Washer 24.Hopper 25. Hopper Liner 26.Tightener Nut 27.Tightener 28. Concave 29 Mantle 30. Mantle Core 31. Release Spring 32.Counter Bearing

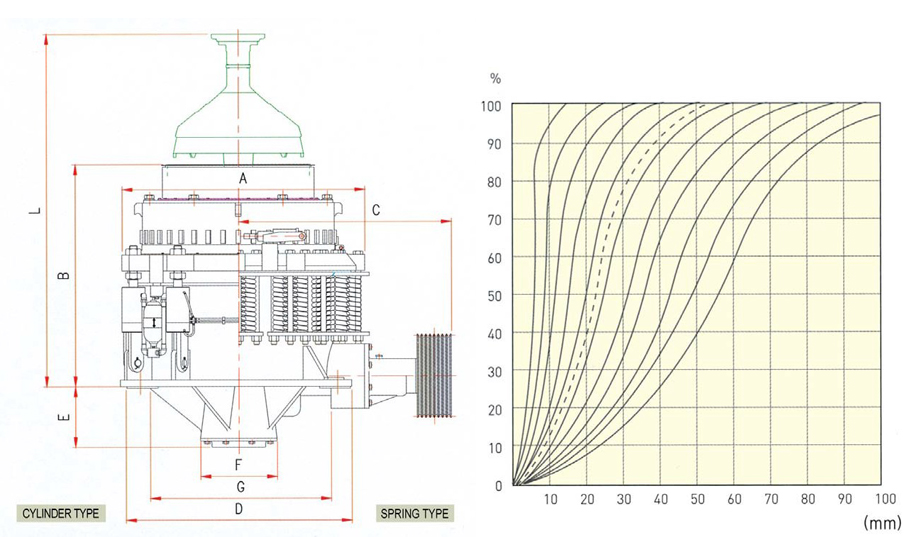

UNITEC-MC DIMENSIONS

| Model | A | B | C | D | E | F | G | L |

| Unitec-MC100 | 1,800 | 1,900 | 1,600 | 1,600 | 410 | 540 | 1,100 | 4,200 |

| Unitec-MC150 | 2,300 | 2,200 | 2,100 | 2,050 | 600 | 680 | 1,300 | 5,100 |

| Unitec-MC200 | 2,500 | 2,150 | 2,050 | 2,200 | 600 | 680 | 1,750 | 5,300 |

| Unitec-MC300 | 2,900 | 2,500 | 2,250 | 2,650 | 750 | 800 | 2,100 | 6,100 |

| Unitec-MC600 | 3,500 | 3,100 | 2,850 | 3,200 | 1,050 | 980 | 2,000 | 7,000 |

Notes:

- The above table is nominal dimensions.

- % passing through a square mesh depending on the given setting.

- The gradation and capacities shown are depended on the feed gradation, the crushing chamber, the material density, the material cleanliness, its moisture and its crushability.

MODEL AND CAPACITY

| F/O(mm) | Crushing Capacity(t/H) | R.P.M | Motor | Approx | |||||||||||

| Model | Closed | Open | Open Setting (mm) | ||||||||||||

| No. | (mm) | (mm) | 6 | 10 | 13 | 16 | 20 | 25 | 30 | 40 | 50 | 60 | (kw) | (W/T) | |

| MCC100 | 150 | 170 | 50 | 60 | 80 | 90 | 100 | 120 | 750 | 75 | 11 | ||||

| MCF100 | 75 | 100 | 30 | 55 | 65 | 75 | 90 | ||||||||

| MCC150 | 200 | 225 | 80 | 100 | 125 | 155 | 180 | 210 | 230 | ||||||

| MCF150 | 100 | 135 | 80 | 100 | 125 | 155 | 650 | 130 | 20 | ||||||

| MCC200 | 210 | 235 | 125 | 150 | 185 | 210 | 250 | 265 | |||||||

| MCF200 | 90 | 120 | 95 | 125 | 150 | 185 | 580 | 160 | 23 | ||||||

| MCC300 | 270 | 305 | 220 | 290 | 335 | 390 | 455 | 480 | |||||||

| MCF300 | 135 | 175 | 145 | 185 | 220 | 260 | 290 | 550 | 220 | 43 | |||||

| MCC600 | 335 | 375 | 410 | 490 | 650 | 810 | 920 | ||||||||

| MCF600 | 190 | 250 | 260 | 310 | 360 | 410 | 440 | 500 | 375 | 72 | |||||

Notes :

- Crushing capacity varies with properties and sizes of raw materials.

- The above table’s capacities are based on clean, dry and brittle materials similar to limestone.

- Capacity based on materials having a bulk density of 1.6 and moisture.