1. Rod Mill and Ball Mill

Rod mills are grinding machine which employ high carbon steel or special steel rods of nearly the same length as that of the drum, in place of steel balls in ball mills. Rod mill products are generally coarser than those produced in a ball mill, and rod mills are well suited to handle coarser feed and to control the top size of the product. Type RO, RE and RC are available for different purposes.

Type RO Rod mill specifications

| Model No. |

Size of Drum Dia×Length (mm) | Capacity (t/h) | Drum (R.P.M) |

Motor (kw) |

Rod Charge (ton) |

||

| Feed 25mm Prod. 20 mesh |

Feed 25mm Prod. 35 mesh |

Feed 25mm Prod. 65 mesh |

|||||

| RO-924 | 900 × 2,400 | 3.55 | 2.85 | 1.8 | 22 | 22 | 2 |

| RO-1224 | 1,200 × 2,400 | 7.2 | 5.75 | 3.6 | 22 | 55 | 5.6 |

| RO-1230 | 1,200 × 3,000 | 8.75 | 7 | 4.4 | 27 | 55 | 6.6 |

| RO-1530 | 1,500 × 3,000 | 14.6 | 11.7 | 7.3 | 24 | 95 | 11 |

| RO-1536 | 1,500 × 3,600 | 17.5 | 14 | 8.75 | 24 | 110 | 13 |

| RO-1830 | 1,800 × 3,000 | 21.2 | 17 | 10.6 | 21 | 150 | 16 |

| RO-1836 | 1,800 × 3,600 | 25.6 | 20.5 | 12.8 | 21 | 150 | 19 |

| RO-2136 | 2,400 × 6,000 | 36 | 29.4 | 18.3 | 19.5 | 220 | 27 |

Type RE, RC mill specifications

| Model No. | Size of Drum Dia×Length(mm) |

Capacity (t/h) Feed 20mm Prod. 5mm |

Drum (R.P.M) |

Motor (kw) |

Rod Charge (ton) |

| RE.RC-924 | 900 × 2,400 | 3.5 ~ 7 | 32 | 22 | 3.4 |

| RE.RC-1230 | 1,200 × 3,000 | 9.4 ~ 17.5 | 27 | 55 | 7 |

| RE.RC-1530 | 1,500 × 3,000 | 17.5 ~ 32 | 24 | 95 | 11.5 |

| RE.RC-1536 | 1,500 × 3.600 | 20 ~ 35 | 24 | 110 | 13.7 |

| RE.RC-1836 | 1,800 × 3,600 | 31 ~ 55 | 21 | 150 | 20 |

| RE.RC-2136 | 2,100 × 3,600 | 45 ~ 73 | 19.5 | 200 | 28 |

| RE.RC-2436 | 2,400 × 3,600 | 63 ~ 100 | 18 | 260 | 37 |

| RC-2442 | 2,400 × 4,200 | 75 ~ 120 | 18 | 300 | 40 |

| RC-3348 | 3,300 × 4,800 | 150 ~ 200 | 14.3 | 630 | 55 |

GRINDING MILLS

Ballmill

Type T Tube Ball Mill can grind materials to a fineness of minus 200 mesh, and is used as a secondary grinding mill after the Type C or Type G Ball Mill.

Type T Ball Mills are to produce a finished product from relatively fine feed in an open or closed circuit. These mills are equipped with thinner shell liners and employ smaller size grinding balls than that of Type C Ball Mill.

Type T Tube Ball Mill specification

| Model No. |

Size of Drum Dia×Length (mm) | Capacity (t/h) | Drum (R.P.M) |

Motor (kw) |

||

| Feed. 10mesh Prod 100mesh |

Feed. 20mesh Prod 200mesh |

|||||

| T-915 | 900×1500 | 0.78 | 0.60 | 38 | 15 | |

| T-918 | 900×1800 | 0.92 | 0.71 | 36 | 19 | |

| T-924 | 900×2400 | 1.20 | 0.93 | 36 | 22 | |

| T-930 | 900×3000 | 1.47 | 1.13 | 36 | 30 | |

| T-1218 | 1200×1800 | 2.02 | 1.56 | 32 | 30 | |

| T-1224 | 1200×2400 | 2.68 | 2.06 | 31 | 37 | |

| T-1230 | 1200×3000 | 3.27 | 2.52 | 31 | 45 | |

| T-1236 | 1200×3600 | 3.87 | 2.98 | 31 | 55 | |

| T-1524 | 1500×2400 | 5.00 | 3.86 | 28 | 55 | |

| T-1530 | 1500×3000 | 6.20 | 4.78 | 27.5 | 75 | |

| T-1536 | 1500×3000 | 7.30 | 5.63 | 27.5 | 75 | |

| T-1542 | 1500×4200 | 8.50 | 6.53 | 27.5 | 95 | |

| T-1830 | 1800×3000 | 10.40 | 8.00 | 25 | 95 | |

| T-1836 | 1800×3600 | 12.40 | 9.50 | 25 | 110 | |

| T-1842 | 1800×4200 | 14.30 | 11.00 | 25 | 150 | |

| T-1848 | 1800×4800 | 15.90 | 12.20 | 25 | 150 | |

| T-2148 | 2100×4800 | 25.70 | 19.80 | 25 | 220 | |

| T-2154 | 2100×5400 | 29.00 | 22.40 | 23 | 220 | |

| T-2448 | 2400×4800 | 36.40 | 28.00 | 21 | 300 | |

| T-2460 | 2400×6000 | 44.70 | 34.00 | 21 | 370 | |

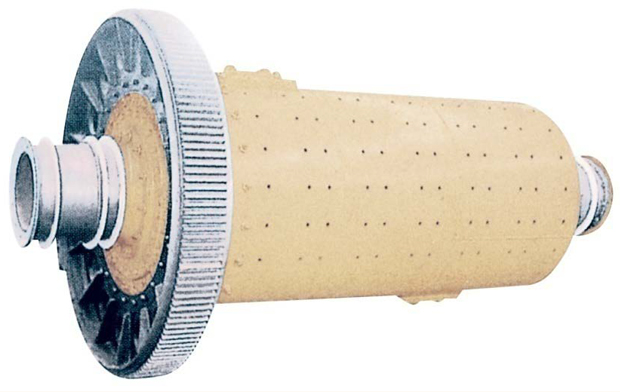

Conical ball mill

Type C Conical Ball Mill has been proved to be a very efficient machine for grinding ore or many other materials in metal mines and other fields. It can grind 8 to 12mm size ore to particles as fine as 50 to 100 mesh.

The conical ball mill operates on the same principle as an ordinary ball mill; however, due to its conical shaped drum, effective graduate size classification of the grinding media-the section of greatest diameter being the largest for coarser grinding and a gradual reduction towards the discharge end for fine-can be obtained. V-belt or directly connected drives can be furnished to the individual requirements for a particular installation.

Grate ball mill

Type G Grate Ball Mill is a cylindrical mill equipped with grate and lifter at the discharge end, designed to be most efficient for coarse grinding in an open or closed circuit with a classifier. Type G Ball Mill can handle 25mm feed. To grind such a large feed efficiently, it comes equipped with thick shell lining and large balls.

Compartment tube mill

Type P Compartment Tube Mill is basically a kind of Type T Ball

Mill. The drum is divided into two to four compartments. The initial or primary grinding compartment is lined with thick liners and carries large balls to accomplish the coarse grinding, while one or more of the secondary compartments are provided with thinner lining and smaller balls. It is suitable for dry grinding in open circuit of calcium cyanamide calcium carbide, cement clinker etc.